Straight out.

What is often said about Hanseatic people also applies to our timing belts. Thanks to sophisticated temperature control during extrusion and constant pre-tensioning of the tension members, crescent formation is not a problem with our timing belts.

You have grown up!

We are continuing on our growth path: by expanding our portfolio and continuously acquiring new customers, we are further expanding our market position.

There is even more...

We are constantly working on expanding our portfolio and look forward to introducing a new product group to you soon.

Stay tuned!

Our Products

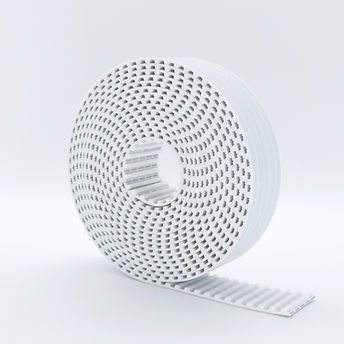

LINEAR PU TIMING BELTS, OPEN LENGTH

Our production line enables the extrusion of linear timing belts in a wide variety of designs. These timing belts consist of a composition of PU (polyurethane), steel or aramid strands and PA fabric on the tooth and/or reverse side.

Our production includes a wide range of standard pitches for linear timing belts, including T5, T10, T20, AT5, AT10, AT20, HTD5M, HTD8M, HTD14M, H, L and numerous other variants. These can be supplied with or without V-guides, either food grade or antistatic.

The particular advantage of our linear timing belts is that their length can be precisely customised to individual customer requirements using our endless welding process.

Further Information

Polyurethane timing belts (PU) are characterised by their excellent length stability and minimal abrasion. Compared to neoprene, polyurethane offers better resistance to chemicals.

These timing belts are produced in rolls and can be cut to length and width as required, allowing for a flexible selection.

For linear drives, the belts are used as open lengths, while welded belts are often used in transport applications.

Thermoplastic polyurethane (PU) can be welded by the metre in any length. The timing belts by the metre are individually cut to the required width and length. The rolls are available in lengths of up to 100 metres (longer on request) and a width of 150 millimetres.